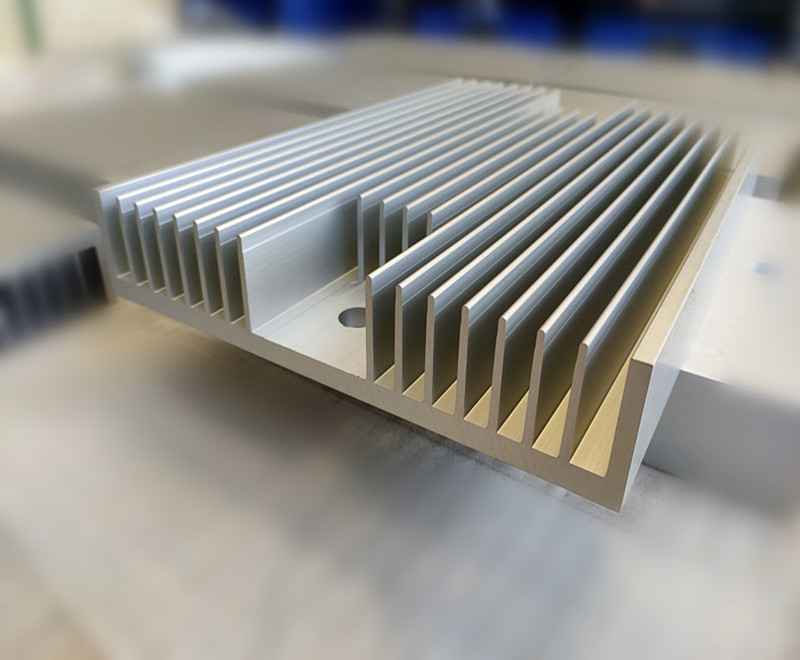

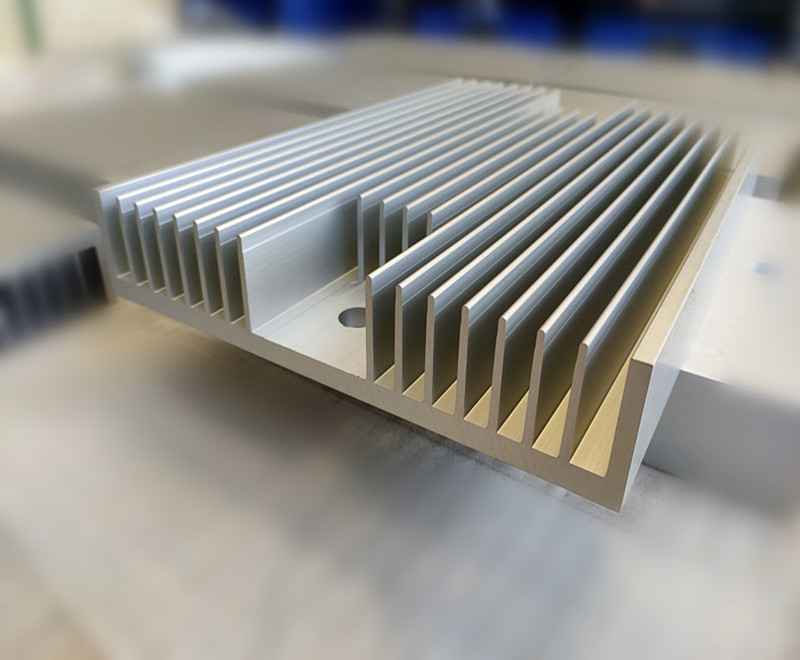

Heatsink Aluminum Profile

Aluminum Heat Sink Profile: A Professional Solution for Thermal Management

In the electronics and lighting industries, temperature control plays a crucial role in enhancing the lifespan and efficiency of devices. One of the most practical tools in this field is the aluminum heat sink profile. With its special design and conductive material, this product absorbs the heat generated by electronic components and transfers it to the surrounding environment, preventing the device from overheating.

What is an Aluminum Heat Sink Profile?

An aluminum heat sink profile is a metallic component, typically made from pure aluminum or aluminum alloys, used for heat dissipation and cooling electronic equipment.

Due to its high thermal conductivity, lightweight nature, and resistance to corrosion, aluminum is considered the best material for manufacturing heat sinks.

Features of Heat Sinks

Excellent thermal conductivity for fast heat transfer

Lightweight compared to metals such as copper

High resistance to rust and corrosion

Can be produced in various shapes and sizes

Anodizing capability to enhance surface durability and aesthetics

Possibility of finned, ribbed, or comb-shaped designs to increase heat dissipation surface area

Advantages of Using Aluminum Heat Sinks

Extends the lifespan of electronic equipment by preventing overheating

Improves the overall efficiency and performance of devices

More cost-effective compared to other metals such as copper

Can be customized based on project requirements

High durability even in harsh environmental conditions

Applications of Aluminum Heat Sink Profiles

Aluminum heat sinks are widely used across various industries, including:

- LED lighting industry: Dissipating heat from LED strips and panels to increase the lifespan of lighting fixtures

- Electronic equipment: Cooling circuit boards, ICs, and sensitive components

- Inverters and power supplies: Preventing damage caused by excessive heat

- Telecommunication industry: Used in antennas, routers, and network devices

- Automotive industry: Managing heat in electronic automotive components

- Industrial machinery: Controlling temperature in drivers and power control systems

Ordering Aluminum Heat Sink Profiles

Why Is an Aluminum Heat Sink the Best Choice?

Compared to other metals, aluminum offers an ideal combination of efficient thermal conductivity, lightweight structure, cost-effectiveness, and high formability. For this reason, aluminum heat sinks are widely regarded as the standard solution in various industries, especially in the LED lighting sector.

Important Factors to Consider When Purchasing a Heat Sink Profile

When choosing this product, it is important to pay attention to the following points:

Dimensions and fin design according to the device’s heat generation level

Quality and purity of the aluminum alloy

Type of surface coating (anodizing or powder coating) to enhance durability

Compatibility of the profile with the specific project (e.g., lighting, electronics, or industrial applications)

Conclusion

Aluminum heat sink profiles are among the most essential components in lighting systems and electronic equipment, playing a key role in extending their lifespan and improving overall performance. Thanks to their unique properties, these profiles hold a significant position across various industries and are recognized as a professional and cost-effective solution for thermal management.